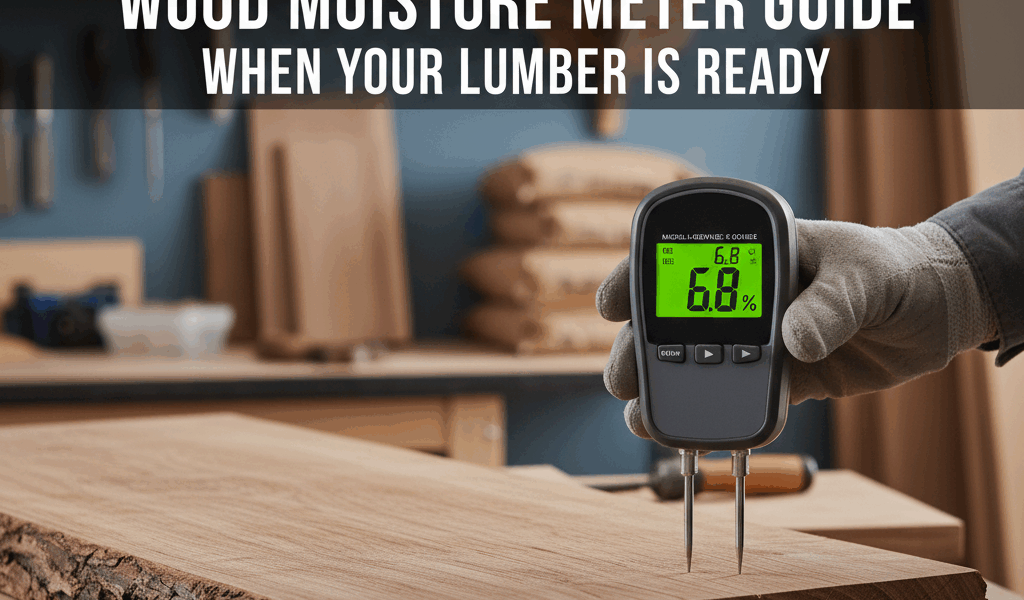

Building furniture with wet lumber leads to warped panels, split joints, and failed finishes. A wood moisture meter eliminates guesswork, telling you exactly when your lumber has dried enough for woodworking. This small investment prevents countless project failures.

Why Moisture Content Matters

Wood constantly exchanges moisture with surrounding air. Lumber milled at 12% moisture content will swell if moved to humid environments or shrink in dry conditions. Building with improperly dried wood causes joints to fail as the wood moves.

Target moisture content depends on your project’s final environment:

- Indoor furniture: 6-8% for heated homes

- Outdoor projects: 12-15% for weather exposure

- Cutting boards: 8-10% for dimensional stability

- Flooring: Match room humidity (typically 6-9%)

Moisture meters provide precise readings, showing when lumber reaches these target ranges.

Pin vs Pinless Meters

Pin-type meters use two metal probes inserted into wood. Electrical resistance between pins indicates moisture content. These meters read moisture at specific depths, useful for checking internal vs surface moisture.

Advantages: Accurate readings, affordable ($30-80), measure specific depths

Disadvantages: Leave small holes, require pin penetration

Pinless meters use electromagnetic sensors scanning wood without penetration. Place the sensor pad against wood surfaces for instant readings.

Advantages: No surface damage, fast multiple readings, scan large areas

Disadvantages: Higher cost ($100-300), surface readings only, affected by surface treatments

Most woodworkers choose pin-type meters for furniture work. The tiny holes left by pins disappear during sanding. Pinless meters suit flooring installers and inspectors who can’t damage finished surfaces.

Reading Depth and Accuracy

Pin meters read moisture at pin depth. Standard pins penetrate 1/4 to 3/8 inches, measuring moisture in this zone. Deep-reading pins (available separately) extend to 1-1/2 inches for thick lumber.

Wood surfaces dry faster than interiors. A board might read 10% at the surface but hold 14% moisture internally. Check thick lumber at multiple depths to ensure uniform drying.

Pinless meters typically read 1/4 to 3/4 inches deep depending on model. They average moisture across the scanning area rather than providing point measurements.

Wood Species Settings

Different wood species conduct electricity differently at the same moisture content. Quality meters include species correction factors or groups.

Common species groups:

- Group A: Douglas fir, pine, spruce (baseline readings)

- Group B: Maple, birch, ash (require +1-2% correction)

- Group C: Oak, walnut, cherry (require +2-3% correction)

- Group D: Exotic hardwoods (corrections vary)

Entry-level meters measure only Group A species. Mid-range models ($50-150) include correction settings for major hardwoods and softwoods. Check your meter’s species list before purchasing if you work with specific woods.

Taking Accurate Readings

Follow these steps for reliable measurements:

- Clean the surface: Remove dirt, finishes, and moisture that affect readings

- Check multiple locations: Test both ends and middle sections

- Insert pins parallel to grain: Across grain readings show artificially high moisture

- Wait for stabilization: Numbers should stop changing within 5 seconds

- Record readings: Track moisture over time during drying

Temperature affects accuracy. Most meters calibrate for 70°F wood. Cold lumber from unheated shops may read artificially high. Bring test boards to room temperature before checking.

Interpreting Your Results

Readings above 20% indicate significant moisture requiring extended drying. Most lumber arrives from suppliers at 12-15% moisture content.

Kiln-dried lumber should measure 6-8% but often gains moisture during storage and shipping. Check kiln-dried boards before using, especially if stored in humid conditions.

Air-dried lumber typically stabilizes at 12-15% outdoors. Indoor storage in heated shops reduces this to 8-10% over several weeks. Track moisture weekly to confirm drying progress.

Aim for moisture content matching your shop’s typical humidity. Build in winter (low humidity) and furniture may shrink when summer humidity rises. Conversely, summer-built projects may develop gaps in dry winter months. Target 7-8% year-round as a safe middle point for most climates.

Drying and Acclimation

Once lumber reaches target moisture content, let it acclimate to your shop for one week minimum. This equalizes moisture throughout boards and matches shop conditions.

Stack boards with stickers (spacer strips) between layers for air circulation. Weight the stack to prevent warping. Fans accelerate drying but avoid direct sunlight which causes checking and uneven drying.

Monitor moisture every few days. When readings stay consistent for one week, lumber is ready for woodworking.

Recommended Meters for Woodworkers

Budget option ($30-40): Basic pin meters with Group A calibration work fine for softwood projects and learning moisture principles.

Mid-range ($60-100): Species correction settings and deeper pin options handle most hardwood projects. These provide accurate readings for serious furniture makers.

Professional ($150-300): Pinless meters or advanced pin meters with extensive species libraries, data logging, and humidity measurement. Worth the investment for full-time woodworkers.

A quality moisture meter pays for itself by preventing one failed project. Test lumber before machining, after drying periods, and before glue-ups. The 30-second test ensures dimensional stability and project success for years to come.

Recommended Woodworking Tools

HURRICANE 4-Piece Wood Chisel Set – $13.99

CR-V steel beveled edge blades for precision carving.

GREBSTK 4-Piece Wood Chisel Set – $13.98

Sharp bevel edge bench chisels for woodworking.

As an Amazon Associate, we earn from qualifying purchases.