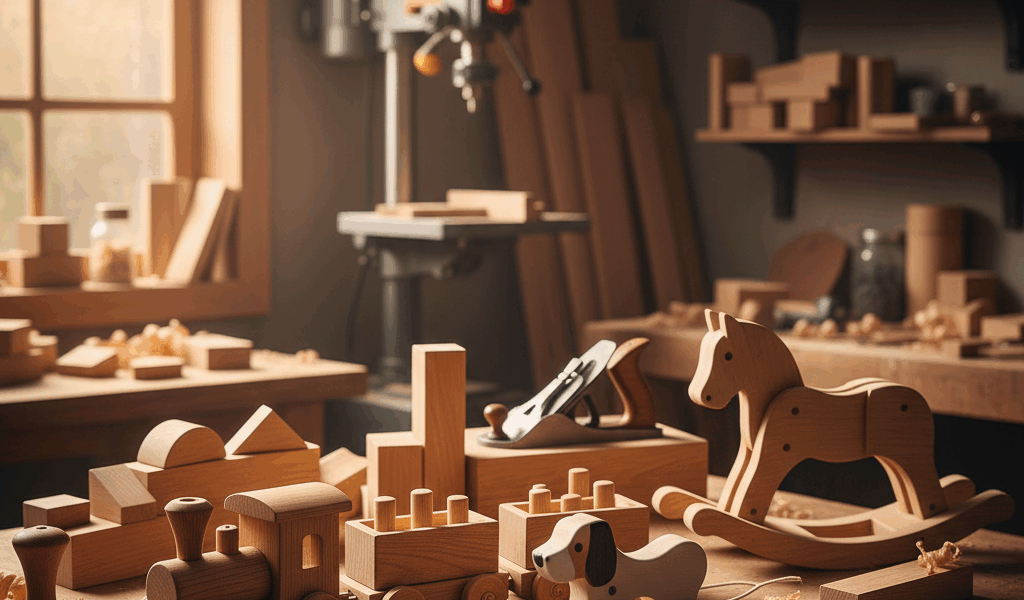

Making Wooden Toys

Handmade wooden toys carry a warmth and durability that plastic can’t match. Whether you’re building for your own children, grandchildren, or craft sales, wooden toys teach fundamental woodworking skills while creating heirlooms that last generations.

Safety Considerations

Toy safety is paramount:

- No small parts: All components must be too large to fit through a toilet paper tube (approximately 1.75″ diameter).

- Smooth surfaces: Sand to 220+ grit with no splinters or sharp edges.

- Non-toxic finishes: Use food-grade finishes, milk paint, or clearly labeled toy-safe products.

- Secure attachments: Wheels and parts must be firmly attached—no easy-to-remove pieces.

- Avoid small hardware: No screws, nails, or staples that could work loose.

Classic Toy Projects

Push/Pull Toys:

- Simple shapes on wheels with a push stick or pull string

- Animals, cars, trains work well

- Use hardwood axle pegs or dowels with wheels

Building Blocks:

- Cut hardwood into various shapes and sizes

- Sand all edges and corners round

- Leave natural or stain with non-toxic colors

- Standard set: rectangles, squares, cylinders, arches

Vehicles:

- Cars, trucks, tractors from solid blocks

- Shape on bandsaw, refine with sanders

- Pre-made wooden wheels available from craft suppliers

Basic Toy Car Tutorial

- Select wood: Hardwood block approximately 2″ x 3″ x 6″

- Draw the profile: Sketch the side view of your car on the wood

- Cut the profile: Bandsaw along your lines

- Shape the body: Round edges with router, rasp, or sandpaper

- Mark wheel positions: Centered left-to-right, appropriate spacing front to back

- Drill axle holes: Size to match your axle pegs (typically 1/4″)

- Sand thoroughly: Progress through 120, 180, 220 grit

- Apply finish: Food-safe oil or wax

- Attach wheels: Glue axle pegs into wheels, then into body. Ensure wheels spin freely.

Wood Selection for Toys

- Best choices: Maple, beech, cherry, walnut—hard and splinter-resistant

- Avoid: Cedar, pine (too soft), oak (splinters), pressure-treated wood (toxic)

- Grain orientation: Avoid short grain in handles or thin sections—they break easily