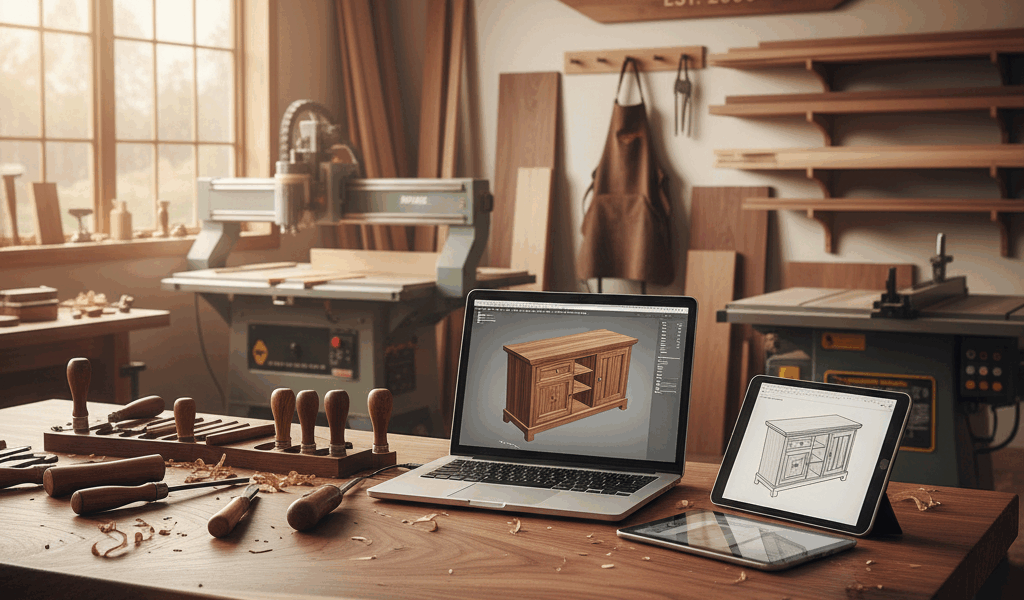

Introduction to Woodworking CAD Software

Woodworking has traditionally required skill and precision. With the advent of CAD (Computer-Aided Design) software, woodworking has become more accurate and efficient. These tools help craftsmen visualize projects, draft precise measurements, and simulate designs before cutting wood.

Benefits of Using CAD Software in Woodworking

CAD software enhances traditional woodworking methods. It eliminates guesswork, reduces waste, and allows you to experiment with designs virtually. This leads to significant cost savings and more consistent quality in completed projects.

Key Features to Look For

When selecting woodworking CAD software, consider its ease of use, level of detail, and available features. Look for tools that offer 3D rendering, a comprehensive library of woodworking joints, and integration capabilities with CNC machines.

Popular Woodworking CAD Software Programs

SketchUp

SketchUp is user-friendly and versatile. It’s suitable for novices and professionals alike. The free version provides basic tools, while the Pro version offers advanced features like layout and style builder. Its 3D warehouse is a valuable resource for downloading and sharing models.

Fusion 360

Fusion 360 is powerful and intuitive. It includes features for 3D modeling, CAD, CAM, and CAE. This makes it an all-in-one solution for woodworking projects. It also allows cloud collaboration, which is beneficial for working in teams.

AutoCAD

AutoCAD is robust and detailed. It’s widely used in various industries, including woodworking. It provides extensive drafting tools, libraries, and compatibility with many file formats. This flexibility is excellent for professional woodworkers handling complex projects.

Vectric Aspire

Vectric Aspire specializes in woodworking and CNC routing. It’s user-friendly and offers powerful 3D modeling tools. Aspire allows you to convert 2D sketches into 3D models easily. It also supports vector drawing and can generate toolpaths for CNC machines.

Using CAD Software in Your Workflow

Begin by designing your project. Use the software to create detailed plans and measurements. Experiment with different materials and finishes virtually. Once the design is finalized, generate the necessary toolpaths or blueprints. This ensures accuracy and efficiency during the cutting and assembly phases.

- Start with basic designs if you are new to CAD software.

- Gradually incorporate more complex features as you become familiar with the tool.

- Regularly save your work to avoid data loss.

- Leverage online tutorials and forums for additional learning and troubleshooting.

Integration with CNC Machines

Many woodworking CAD programs integrate seamlessly with CNC machines. This enables automated cutting and milling based on your designs. Integration helps in achieving precision and reducing manual effort. Ensure your CAD software is compatible with your CNC machine’s requirements.

Cost Considerations

CAD software ranges from free to expensive. Evaluate your budget and project needs before investing. Many premium programs offer trial versions, so test them before committing. Free versions or lower-cost subscriptions may suffice for hobbyists or small-scale projects.

Resources for Learning and Improvement

Utilize online resources to sharpen your CAD skills. Websites, video tutorials, and forums are excellent sources of information. Many software websites offer thorough documentation and support communities. Regular practice will help you master the software and improve your woodworking projects.

Conclusion

Woodworking CAD software revolutionizes how woodworkers design and execute their projects. It offers precision, efficiency, and the ability to visualize complex designs. Selecting the right software based on your needs and budget can significantly enhance your woodworking endeavors.

“`