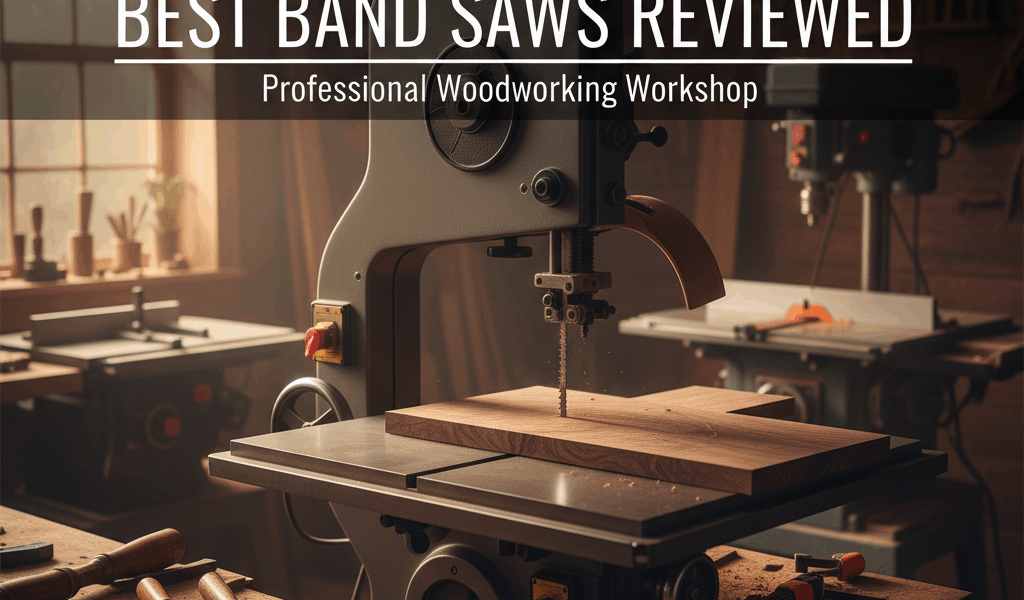

Best Band Saw: A Comprehensive Guide

Choosing a band saw has gotten complicated with all the specs and brand comparisons flying around. As someone who has used band saws for everything from resawing lumber to tight curved cuts in furniture work, I’ve learned what actually separates a great saw from a frustrating one. Today, I’ll share what I know.

Understanding Band Saw Features

The features that matter most are the ones that affect your actual cuts — blade size, guide system, motor power, and table design.

- Blade Size: Blade width determines what you can cut. Wider blades are more stable for straight cuts; narrower blades maneuver better for curves. Match blade width to the work you do most.

- Blade Guide System: This holds the blade in place and prevents twisting. Block guides work, but bearing guides provide more precise control and less friction. Worth the upgrade if you’re choosing between configurations.

- Motor Power: Measured in horsepower. More HP means the saw handles harder and thicker materials without bogging down. For dedicated hardwood work, don’t undersize the motor.

- Table Design: A stable, adjustable table with tilt capability and a solid fence makes precise cuts repeatable. These details matter a lot for daily use.

Top Band Saw Models

1. Jet JWBS-14DXPRO

A high-end band saw known for durability and performance. Key specs:

- 14-inch cutting capacity

- 1-1/4 HP motor

- Two-speed poly-V belt drive system

- Sturdy cast-iron frame

- Large, tilting table

The two-speed drive adds real flexibility for cutting different materials. Built for professional and serious hobbyist use. I’m apparently a cast-iron table person — the rigidity works for me while lighter aluminum tables always feel like they’re flexing.

2. Rikon 10-324TG

A mid-range saw with excellent features for the price:

- 13-inch cutting capacity

- 1-1/2 HP motor

- Two-speed settings (1,515 and 3,280 FPM)

- Tool-less blade guide adjustments

- Large cast-iron table with 45-degree tilt

The tool-less blade guide adjustments make blade changes genuinely quick. The two-speed settings handle material variety well. Good value at the mid-range price point.

3. WEN 3962

A budget-friendly option that handles most common tasks:

- 10-inch cutting capacity

- 3.5 Amp motor

- Two-speed operation (1,520 and 2,620 FPM)

- Spacious work table with 45-degree tilt

- Built-in work light

Great entry-level saw for hobbyists or beginners. The smaller motor limits it on thick hardwoods, but for most projects it’s capable. The built-in work light is a genuinely useful feature for accuracy.

Choosing the Right Band Saw

Match the saw to your actual work. Professionals doing heavy resawing need a different machine than a hobbyist making furniture. Read user reviews that mention the saw after a year of use, not just unboxing impressions. Check parts availability and warranty before committing.

Band Saw Maintenance Tips

Regular maintenance keeps the saw cutting cleanly and safely:

- Inspect the blade for wear and damage before each session

- Clean the blade and table regularly

- Adjust blade tension and tracking as needed

- Lubricate moving parts per the manufacturer’s guidelines

- Check blade guide and bearing alignment periodically

Tips for Safe Use

- Wear safety glasses and hearing protection.

- Ensure the blade is properly installed and tensioned before starting.

- Keep hands away from the blade; use push sticks on narrow pieces.

- Secure the workpiece before cutting — a piece that shifts causes kickback.

- Unplug before making any adjustments or changing blades.

Common Band Saw Blade Types

- Hook-Tooth Blades: Fast, aggressive cutting. Best for hardwoods and dense materials.

- Skip-Tooth Blades: Smoother cuts. Better for softer woods and plastics.

- Regular-Tooth Blades: A balance between speed and smoothness. Good general-purpose option.

How to Change a Band Saw Blade

- Unplug the saw.

- Release blade tension using the tensioning mechanism.

- Remove the blade from the upper and lower wheels.

- Install the new blade, positioning it correctly on both wheels and through the blade guides.

- Tension the blade per the manufacturer’s specs.

- Check tracking and adjust so the blade runs straight.

Consult your saw’s manual for model-specific details. A correctly changed and tensioned blade is the foundation of every accurate cut you’ll make.