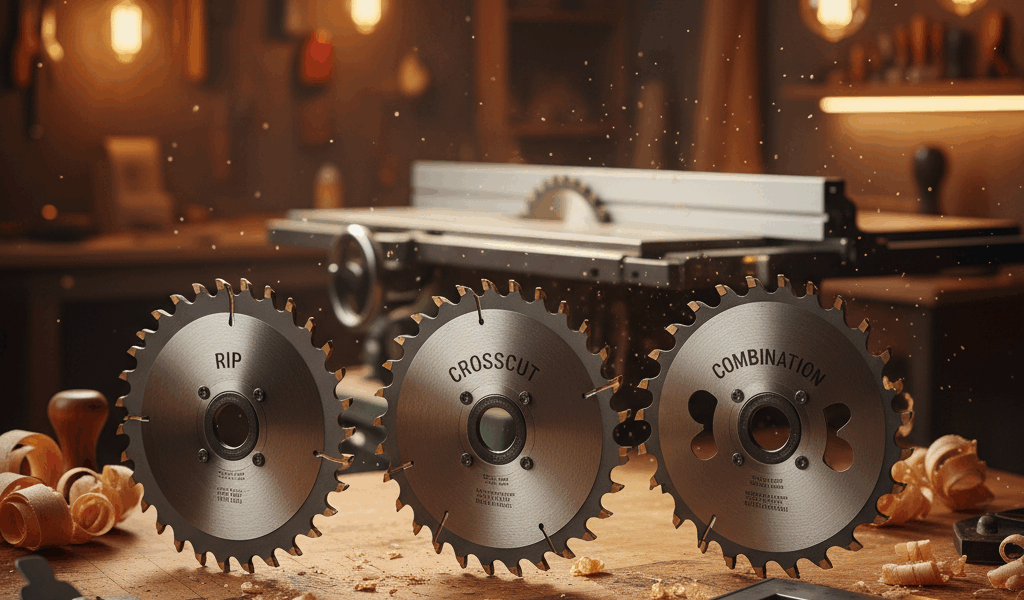

Table saw blades come in three main configurations: rip blades for cutting with the grain, crosscut blades for cutting across the grain, and combination blades that handle both tasks. Each design optimizes tooth geometry for specific cutting actions.

Rip Blade Design

Rip blades have fewer teeth—typically 24 to 30 on a 10-inch blade. The larger gullets between teeth provide chip clearance when cutting with the grain. The flat-top grind (FTG) on each tooth acts like a chisel, efficiently removing material along the length of the board.

The hook angle on rip blades ranges from 10 to 20 degrees positive. This aggressive angle pulls the blade through the wood with less feed pressure required. The combination of fewer teeth, large gullets, and positive hook angle produces fast rip cuts with minimal motor strain.

Crosscut Blade Characteristics

Crosscut blades pack 60 to 80 teeth on a 10-inch blade. The high tooth count produces smooth cuts across wood grain by taking smaller bites. Each tooth features an alternate top bevel (ATB) grind that scores wood fibers cleanly rather than tearing them.

The hook angle is neutral or slightly negative—typically 0 to 5 degrees. This reduces the blade’s tendency to self-feed, giving you better control during crosscuts. The shallow or negative hook also reduces tear-out on the bottom face of the board.

Combination Blade Compromise

Combination blades split the difference with 40 to 50 teeth on a 10-inch blade. The tooth pattern alternates between groups of ATB teeth and flat-top raker teeth. The ATB teeth score the wood fibers, while the raker teeth clear material from the kerf.

The hook angle runs 10 to 15 degrees—enough bite for efficient ripping without excessive self-feeding during crosscuts. This middle-ground design handles both cut types adequately without excelling at either.

Cut Quality Comparison

A dedicated rip blade leaves crosscuts with noticeable tear-out and rough edges. The coarse teeth tear across grain fibers rather than slicing them cleanly. You’ll need to sand or plane crosscut edges if appearance matters.

A crosscut blade makes slow work of rip cuts. The high tooth count creates excessive friction and heat in long grain cuts. The motor bogs down and the blade may overheat in thick hardwoods. Cut quality is fine, but efficiency suffers.

A combination blade delivers acceptable results in both operations. Crosscuts show slightly more tear-out than a dedicated crosscut blade but remain clean enough for most work. Rip cuts proceed slower than with a rip blade but maintain reasonable feed rates.

Feed Rate Differences

With a rip blade, you can push 8/4 hardwood through at a steady walking pace. The coarse teeth clear chips quickly without bogging the motor. The aggressive hook angle pulls the work through with minimal back pressure.

The same cut with a crosscut blade requires slower feed rates. Push too fast and the motor strains, the blade heats up, and cut quality deteriorates. You might cut feed speed by 40-50% compared to a rip blade.

A combination blade splits this difference, requiring somewhat slower feeds than a rip blade but faster than a crosscut blade in the same material.

Best Uses

Use a rip blade when:

- Breaking down sheet goods or rough lumber

- Ripping multiple boards to width

- Cut quality isn’t critical

- You’re working with thick or hard material

Use a crosscut blade when:

- Cutting parts to final length

- Working with veneered plywood

- Cut edges will be visible in the finished project

- You need minimal sanding after cutting

Use a combination blade when:

- You only want one blade on hand

- Your work mixes ripping and crosscutting

- Blade changes aren’t practical in your workflow

- Cut quality needs are moderate rather than critical

Blade Changes

Swapping blades takes 2-3 minutes including height adjustment. If you’re doing dedicated ripping or crosscutting sessions, changing blades pays off in cut quality and efficiency. For mixed work where you alternate between cut types frequently, the time spent changing blades eats into the efficiency gains.

Some shops keep two table saws set up—one with a rip blade, one with a crosscut blade. This eliminates blade changes entirely but requires the space and budget for two saws.

Recommended Woodworking Tools

HURRICANE 4-Piece Wood Chisel Set – $13.99

CR-V steel beveled edge blades for precision carving.

GREBSTK 4-Piece Wood Chisel Set – $13.98

Sharp bevel edge bench chisels for woodworking.

As an Amazon Associate, we earn from qualifying purchases.