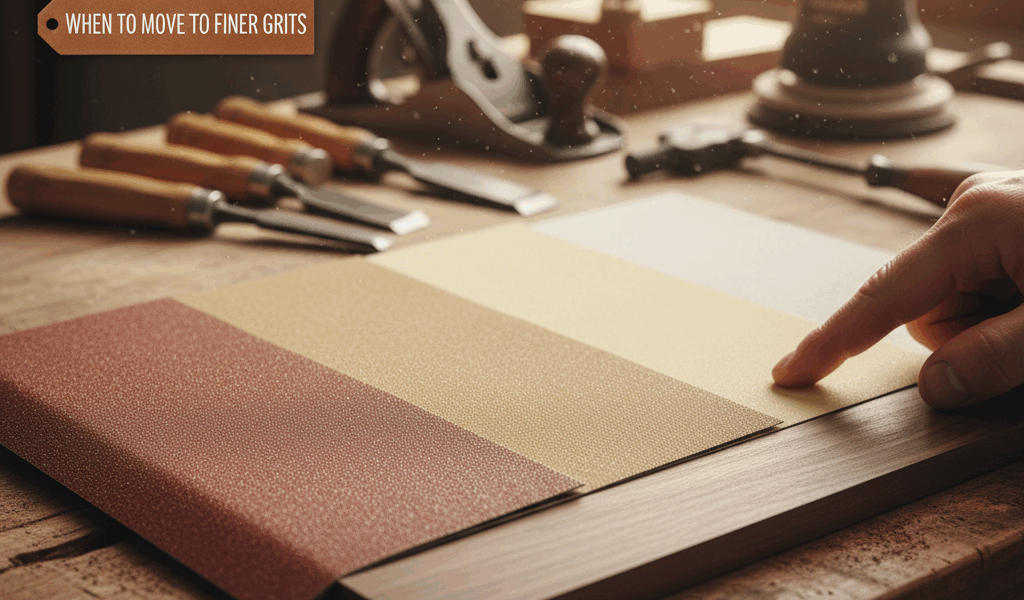

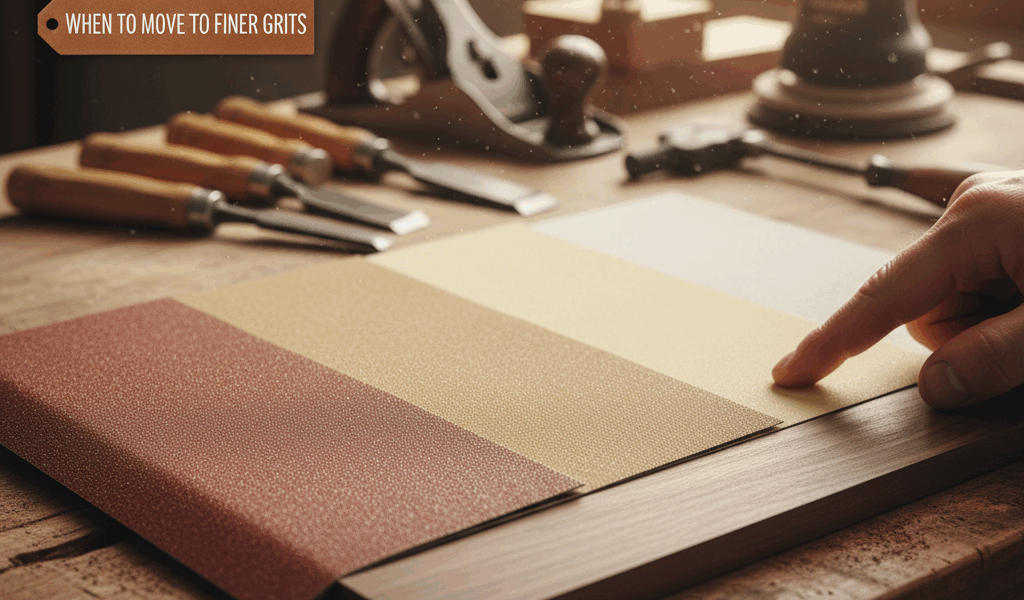

Sanding progression determines surface smoothness and affects how well finishes adhere and appear. Skipping grits leaves visibl

Sandpaper Grit Sequence: When to Move to Finer Grits

Sanding progression determines surface smoothness and affects how well finishes adhere and appear. Skipping grits leaves visibl