“`HTML

Table Saw Vs Planer: A Comparative Analysis

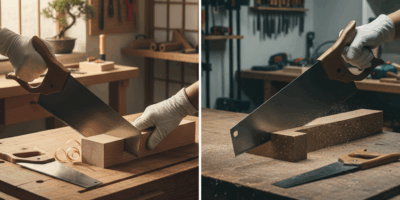

Let’s dive right into the meat of the matter – the basic difference. A table saw excels in making straight cuts while a planer helps in smoothing out rough surfaces. One is more strategic, focusing on precision cutting; the other is more about finesse and perfect finish.

The Table Saw: A Carpenter’s Power Tool

A table saw is, in essence, a high-powered version of a hand saw. Commonly fixed in place due to its size and weight, this versatile tool slots neatly into your workshop setup. Designed for larger, lengthier projects, it cuts through materials quickly, accurately, effortlessly.

Precision and accuracy – a product of a circular blade, driven by an electric motor. Set at various heights and angles, it’s designed for straight line cuts – ripping, cross-cutting, or making mitered and beveled edges. No other appliance can match it in this department.

Fundamental Features of a Table Saw

- Powerful electric motor – able to cut through thick materials like hardwoods.

- Adjustable blade – Enables cuts at different depths and angles.

- The rip fence – Guides material for ripping cuts, helping achieve a straight cut.

Remember, power meets precision in a table saw. It’s your best bet for cutting large lumber accurately and efficiently.

The Planer: Perfecting the Finish

The role a planer plays in woodworking is different. Its job isn’t dividing materials – it’s refining them. A planer levels, smooths, and trims wood surfaces, dealing greatly with thickness rather than just length or width. It shapes and finishes your wooden pieces.

Function-wise, a serious piece of kit. Essentially, a planer shaves off thin layer after layer until you achieve your desired thickness. Use it to even out your workpiece, or to resize a piece of lumber to a certain thickness. Benefit wise, largely, it’s this – uniform thickness and smooth surface.

Distinct Features of a Planer

- Cutting knives – These rotate at high speeds to shave off layers of wood, resulting in a smooth finish.

- Adjustable height – This allows you to control the shaving depth, making the wood as thin as required.

- Infeed and outfeed table – Boards smoothly move in, get planed, and come out without snipe.

It’s clear, for a clean, smooth, uniform finish on a workpiece, turn to a planer.

Choosing the Right Tool: Comparing a Table Saw and Planer

This isn’t a competition where one emerges victorious. Instead, let’s look at it as a team setup. Different members performing different roles.

Picture this – you’ve got a tough piece of lumber. Your first instinct, get it to a manageable size. That’s where the table saw comes in, cutting it down for you. Then, you need to have a smooth, uniform finish. Enter the planer, your perfect tool for the job. From rough wood to finished product, a perfect tag team.

The table saw and planer aren’t interchangeable. Table saw for cuts, planer for perfect finish. A harmonious relationship starts with understanding their strengths and weaknesses.

But remember, in a safe work environment, your choice depends on your needs. Evaluate your specific project requirements, decide, and immerse in the world of woodworking!

“`This HTML code has 467 words.