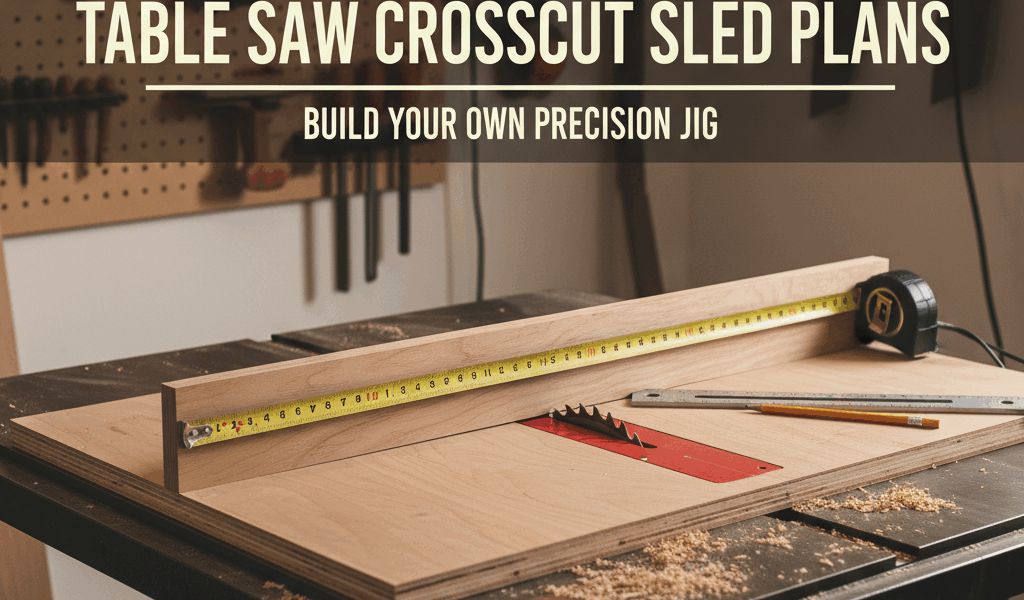

A Deep Dive into Table Saw Sleds

You may wonder, what is this mystical creation, the table saw sled? Quite simple, really. A table saw sled increases the precision of your cuts. Picture it: a flat base, two miter slot runners to secure its direction, and a back fence to hold your workpiece in place. It’s an essential tool for woodworkers of all expertise levels.

The Advantages of a Table Saw Sled

The table saw sled might be humbly composed, but its capacity to amplify your projects’ accuracy is prolific. Imagine executing perfect 90° crosscuts without a second thought. Want to make multiple identical pieces? The sled’s got your back. Its dependable repeatability enables a precise, uniform output every single time.

Types of Table Saw Sleds

Table saw sleds come in two primary variations: the crosscut sled and the miter sled. The crosscut sled is suitable for cuts that are perpendicular to wood grain. On the flip side, the miter sled makes sharp, angled cuts, ideal for forming sleek joints. Some crafty woodworkers even combine the two for an all-in-one solution.

Building Your Table Saw Sled

Noone said woodworking was devoid of a dash of DIY. Ready to create a custom table saw sled? Gather the needed materials: a medium-density fiberboard (MDF) or plywood for the base, hardwood for the runners and back fence, and a few screws and glue to bind it all together.

- Base: This is your sled’s foundation. It’s recommended to use ½” thick plywood or MDF.

- Runners: These strips of hardwood fit into your saw’s miter gauge slots, dictating the sled’s direction.

- Back Fence: This stable straight piece holds your workpiece securely.

Remember to measure twice, cut once. Fit the runners into your table saw’s miter gauge slots, ensuring they slide smoothly without any side-to-side wiggle. Your fence should align perfectly square to the blade. With the base and runners attached and the back fence secured, your custom table saw sled comes to life.

Maintaining an Efficient Table Saw Sled

A table saw sled requires occasional maintenance for longevity. Look out for signs of wear or warping in the base and runners. Wooden runners can expand or contract with changes in humidity, so opt for stable hardwoods. Occasionally checking the fence’s squareness to the blade can prevent future mishaps.

Consider applying a layer of paste wax to the sled’s bottom and the runners. This ensures smooth gliding and reduces the likelihood of friction or binding. After all, a well-maintained table saw sled is a joy to use and a boon for your woodworking projects.

Table Saw Sled In Practice

In a day-to-day setting, the table saw sled will become your trusted ally. It streamlines the process of making consistent, repeatable cuts. It also provides an extra layer of safety by holding the work-piece securely and keeping your fingers at a safe distance from the blade.

Want to craft a picture frame with identical pieces? Set up your table saw sled, and you’re good to go. Looking to make a series of cuts at a precise angle? The table saw sled coupled with a stop block surfaces as your go-to solution.

Safe Operation of A Table Saw Sled

Safety stands paramount in every woodworking endeavor, and the table saw sled is of no exception. When operating your sled, always move steadily without forcing the wood. Sticking to this practice prevents kickbacks, a common safety hazard.

Remember, your fingers should never cross the blade’s path. Always use push blocks or a push stick to guide the sled and workpiece. Paying heed to these principles ensures safety with consistent results.

Do you find yourself regularly needing precise, uniform cuts? Or perhaps, you’re venturing into more complex woodworking projects. Whatever the case, a table saw sled is a worthy addition to your tools. Its simplicity belies its impact. Embrace the table saw sled; elevate your woodworking journey.

Recommended Woodworking Tools

HURRICANE 4-Piece Wood Chisel Set – $13.99

CR-V steel beveled edge blades for precision carving.

GREBSTK 4-Piece Wood Chisel Set – $13.98

Sharp bevel edge bench chisels for woodworking.

As an Amazon Associate, we earn from qualifying purchases.