Shop saws have gotten complicated with all the panel saw options and conflicting advice flying around. As a woodworker who has broken down a lot of sheet goods over the years, I’ve learned what separates a genuinely useful panel saw from an expensive frustration. Today, I’ll share everything I know about the sliding carriage panel saw.

What is a Sliding Carriage Panel Saw?

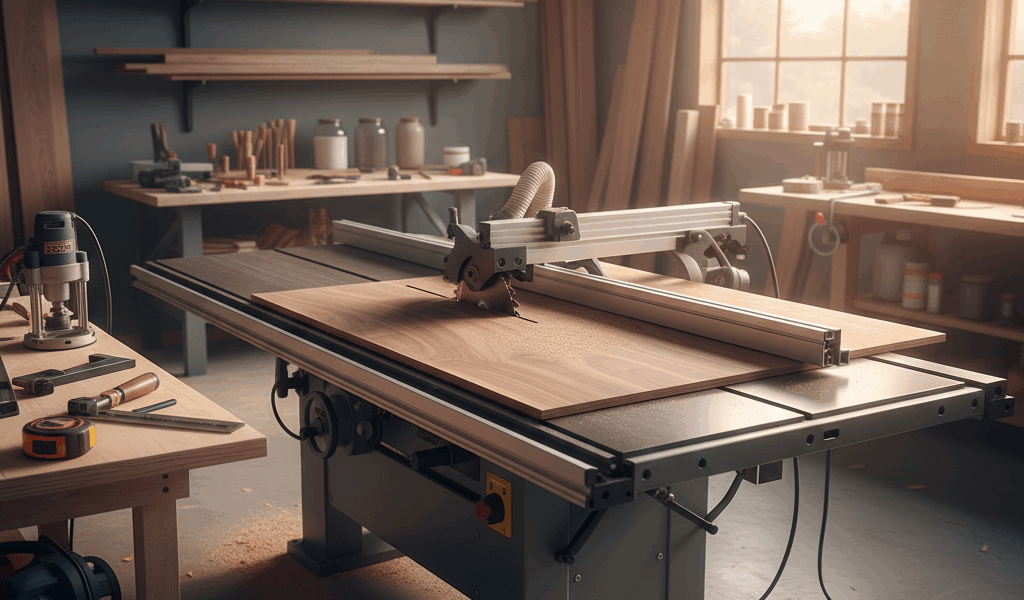

Central to many woodworking shops, the sliding carriage panel saw is a versatile and powerful tool. It’s a saw with a mobile table integrated into the saw bench. This unique design allows for precise, smooth cuts, making it a favored choice for anyone who regularly works with large sheet material.

Design and Operation

A sliding carriage panel saw’s main feature is its mobile table or carriage, fixed to a rail system that slides smoothly back and forth. The saw blade protrudes through a slot in the table, cutting through material placed on the table surface as the carriage travels. The configuration provides excellent control and steadiness — the workpiece moves past the blade rather than the other way around.

The saw blade’s knobs adjust height and angle for bespoke cutting needs. Many saws also include scoring blades — small diameter blades rotating opposite to the main blade that reduce chip-out in laminated or veneered material. That scoring feature is what makes the difference on cabinet work.

Main Uses

A sliding carriage panel saw excels at cutting large panels or sheet goods — the kind of cuts that are difficult to make accurately with a circular saw and a straight edge, and outright dangerous to attempt freehand with a standard table saw. Beyond straight cuts, the saw accommodates angled cuts, expanding its usefulness considerably. Cabinet makers, furniture builders, and serious hobbyists consider this saw an indispensable shop tool.

Types of Sliding Panel Saws

Manual Sliding Panel Saws — The user operates the sliding carriage manually, drawing it back and forth through the cut. Cost-effective and capable, though more physically demanding for production work.

Automatic Sliding Panel Saws — Motorized versions that use an electric motor to move the carriage along the rail system. Ideal for high-volume work. They’re more expensive, but if you’re breaking down hundreds of panels a week, the efficiency is worth the investment. I’m apparently a “manual saw for the shop, automatic for the production floor” person and that distinction always works better for me while treating both as interchangeable never does.

Choosing the Right Saw

Space

Most sliding carriage panel saws require substantial space for the carriage’s full range of motion — the saw itself isn’t the footprint concern, the travel path is. Compact models exist for smaller workshops, but the tradeoff is panel capacity.

Project Needs

If precision and clean edges on large panel cuts are what you need, a model with a scoring blade is worth the premium. For occasional sheet good cuts in a hobby shop, a manual saw without scoring will still outperform a circular saw with a guide in both accuracy and convenience.

Budget and work volume will ultimately decide between manual and automatic. Either way, having a sliding carriage panel saw changes how you approach a whole category of work.

Maintenance

Maintaining a sliding carriage panel saw is straightforward. Regularly clear sawdust and debris from the sliding mechanism — buildup creates friction that affects both accuracy and carriage feel. Lubricate the rail system lightly to maintain smooth travel. Check bolts and fasteners periodically; vibration loosens things over time. The blade will need sharpening or replacement based on usage — a dull blade shows in cut quality long before it becomes obvious.

Safety

Understanding how the tool works is the foundation of safe operation. Use the provided safety guard and don’t remove it for convenience. Stand to one side during the cut rather than directly behind the blade — kickback on a panel saw is rare but not impossible. Get trained on your specific saw’s features before using it in production. Safety with any stationary saw is non-negotiable, and a sliding carriage panel saw is no exception.