Unleashing the Power of Cut List Optimizer

Any professional in the woodworking or metalworking industry knows that efficiency is crucial. It’s one pivotal aspect where a gem like cut list optimizer shines.

What is a Cut List Optimizer?

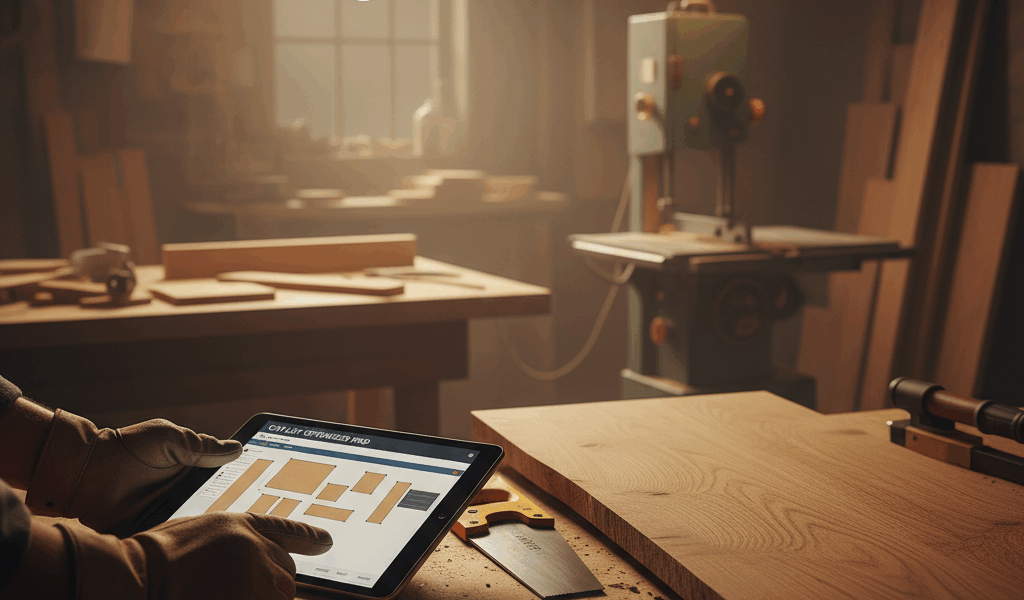

A cut list optimizer could be rightfully called a game-changer. Overly simplified, it’s software designed to minimize material waste in cut jobs. But don’t let the simplicity of the definition fool you. This compact solution holds profound value for those seeking to make the most out of their resources.

It’s a tool that takes predefined cutting lists and material dimensions, then calculates the optimal cutting patterns. Depending on the software provider, such tools might also include additional features like cost calculation, inventory management, and production planning.

Why Cut List Optimization Matters?

The importance of an effective cut list optimizer shouldn’t be undervalued. Resource management is front and center for all kinds of industries, especially in woodworking or metalworking. Material waste should be minimized not only from a financial point of view but also for environmental considerations.

Through effective optimization, businesses can save significant amounts of raw materials, decrease waste, reduce labor hours, and improve overall productivity. It all translates into considerable cost savings.

Key Features of a Quality Cut List Optimizer

So, what makes a good cut list optimizer? There are a handful of core features to look for when choosing a solution like this.

- Powerful optimization algorithm: The heart of the system; it should be capable of efficiently processing complex cutting lists.

- User-friendly interface: A self-explanatory, intuitive interface is essential.

- Flexibility: The software should cater to different materials, dimensions, and cutting techniques.

- Multi-Shape optimization: A capable optimizer should handle different shapes not only rectangles.

Maximizing Productivity with a Cut List Optimizer

At a glance, a cut list optimizer’s primary function is to save on materials and reduce waste. But take a moment and look deeper. It’s an essential tool that has the potential to significantly impact business processes and overall operational efficiency.

When utilized efficiently, such software can not only reduce material waste but also streamline project planning, alleviate the burden of complex calculations from workers, and speed up the manufacturing process. As such, cut list optimizers can lead to heightened productivity and increased customer satisfaction.

The Environmental Impact of Using a Cut List Optimizer

Let’s not forget the environmental implications. The more businesses can conserve raw materials, the better for the environment. And with a robust cut list optimizer, achieving substantial materials saving becomes a practical reality, not just wishful thinking.

Reducing material usage means less waste and fewer resources spent on disposal or recycling of scraps. This reduction in consumption also results in less demand for raw materials, which, in the grand scheme, leads to a lower carbon footprint- an admirable stride for any business towards sustainability.

Choosing the Right Cut List Optimizer

Given their importance, it’s crucial to take time and ensure you choose the right cut list optimizer for your business. Keep functionality, ease-of-use, and flexibility in mind. Also, read reviews, ask for recommendations, and don’t shy from trying free trials. Seizing the most suitable tool is a vital step towards business efficiency and financial effectiveness.