The Essential Guide to the Mitre Sled

Building and using a mitre sled has gotten complicated with all the jig designs and fence-angle debates flying around. As someone who built my first mitre sled years ago and has refined the design through several iterations, I’ve learned what actually matters for repeatable, accurate cuts. Today, I’ll share everything I know.

Understanding the Mitre Sled

A mitre sled is a table saw fixture built to improve cutting accuracy — particularly for angled cuts like mitres for frames and joints. It consists of a flat base that slides in the table saw’s slots, holding workpieces securely at specific angles. A mitre sled offers greater stability and precision than a standard mitre gauge, especially on larger or longer pieces.

The two main components are the base and the fences. The base is typically plywood or MDF — flat, stable, smooth-sliding. The fences are attached at specific angles to the blade, and adjusting them gives you a variety of cut angles.

Components of a Mitre Sled

Base

The base is the foundation. Flat and sturdy material is critical — any warp in the base transfers directly to inaccuracy in your cuts. Plywood and MDF are the standard choices. A smooth surface ensures the sled slides effortlessly on the saw table.

Fences

The fences guide the workpiece and hold it at a precise angle during cutting. Hardwood fences work well for most applications; aluminum or metal fences add durability and precision for higher-end builds. The fences need to be dead straight — any bow or twist in a fence compromises every cut you make.

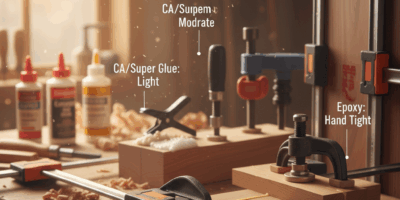

Fastening Mechanisms

Clamps hold the workpiece in position during the cut. Stop blocks allow for repeated cuts of the same length without remeasuring. These components turn a basic sled into a production-capable tool.

Slides

The runners fit into the table saw’s mitre slots. Fit is everything here — tight enough that there’s no play, smooth enough that the sled glides without binding. Getting the runner fit right is the most critical step in building a sled that performs.

Advantages of Using a Mitre Sled

Precision

Repeatable accuracy across multiple cuts — that’s the whole point. A well-built sled delivers the same cut consistently whether you’re making the second piece or the twentieth.

Safety

The sled keeps your hands away from the blade and maintains better control over the workpiece, reducing kickback risk. Safety guards and holding clamps that come with some designs add another layer of protection.

Versatility

Adjustable fences handle a wide range of angles. Picture frames, box joinery, complex cabinetry — a mitre sled adapts to all of it. That versatility is what makes it endearing to us woodworkers — it’s one jig that does a lot of different jobs well.

Improved Workflow

Set the sled once for a task and repeat cuts without constant recalibration. For production work or any project with repetitive parts, this efficiency adds up fast.

Building Your Own Mitre Sled

Building a mitre sled is one of the most useful shop projects you can do. It’s practical, customizable, and a good introduction to precision jig-making.

Tools and Materials Needed

- Table Saw

- Plywood or MDF for the base

- Hardwood strips for the runners

- Hardwood for fences

- Clamps

- Wood Screws

- Measuring tape

- Square and protractor for angle settings

- Drill and drill bits

Step-by-Step Construction

Cut the base to size based on your table saw and the maximum workpiece size you’ll handle. A typical sled base runs 18-24 inches by 24-36 inches — adjust for your situation.

Cut the runners to fit snugly in the saw’s mitre slots. They should fit tightly enough to eliminate play but slide smoothly without binding. This fit is worth getting right before moving forward.

Attach the runners to the base. Place them in the mitre slots, set the base over them, and secure with screws. Verify alignment by sliding the sled back and forth and adjust as needed before the screws are fully set.

Cut and attach the fences from hardwood — straight, true stock only. One fence at 90 degrees for square cuts, one at 45 degrees for mitres is the standard configuration. Secure with screws and verify the angles with a square or protractor.

Add stop blocks and clamps for your specific projects. Test with scrap wood, check angles, and make fine adjustments before using the sled on actual material.

Common Uses and Techniques

Picture Frames

Accurate mitre cuts produce tight-fitting corners. A mitre sled makes picture frame work faster and more consistent than any other approach.

Boxes and Cabinetry

Accurate right-angle joints for box construction and cabinet assembly. The sled simplifies the process of joining panels precisely.

Complex Angles

Adjustable fences handle angles that are awkward with other tools. Expanded creative possibilities for furniture and architectural details.

Repetition and Accuracy

Set up once, cut the same dimension repeatedly without re-measuring. This is where the sled saves the most time on real projects.

Maintaining Your Mitre Sled

Check the base periodically for warping — moisture absorption can affect MDF especially. Re-seal or replace if it’s no longer flat. Lubricate the runners to maintain smooth glide. Check fence alignment with a square regularly and tighten any loose screws before they cause a bad cut.

A well-built mitre sled, properly maintained, is genuinely indispensable in a woodworking shop. It provides stability, precision, and efficiency on a wide range of cuts that would otherwise require more setup and more risk.

Recommended Woodworking Tools

HURRICANE 4-Piece Wood Chisel Set – $13.99

CR-V steel beveled edge blades for precision carving.

GREBSTK 4-Piece Wood Chisel Set – $13.98

Sharp bevel edge bench chisels for woodworking.

As an Amazon Associate, we earn from qualifying purchases.