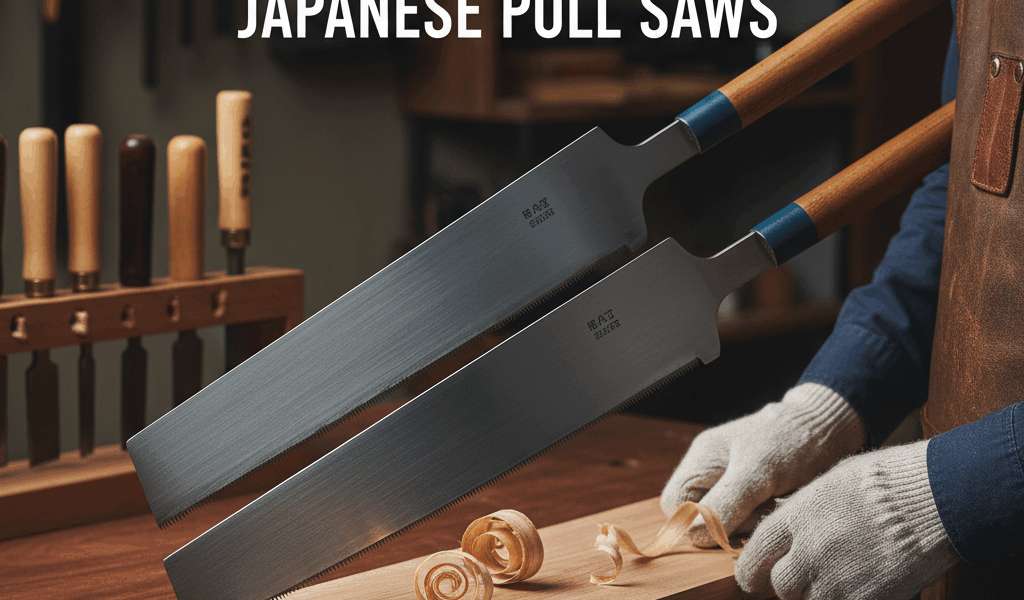

Japanese pull saws cut on the pull stroke rather than the push stroke, offering several advantages for precision woodworking.

Why Pull Saws Work Better

The thin blade stays rigid under tension during the pull stroke. This allows for finer teeth and thinner kerfs than Western push saws. Less material removal means less waste and cleaner cuts.

Three common types serve different purposes:

- Ryoba – Double-sided with crosscut teeth on one edge and rip teeth on the other

- Dozuki – Fine-toothed backsaw for joinery and precise cuts

- Kataba – Single-sided blade without a spine for deeper cuts

Getting Started

Begin with a ryoba saw in the 240mm blade length. This size handles most workshop tasks from rough cuts to joinery prep.

Grip the handle lightly. Let the saw’s weight do the work on the pull stroke. Apply minimal pressure and focus on keeping the blade straight.

Mark your cut line with a marking knife rather than a pencil. The knife creates a groove that guides the saw teeth for a cleaner start.

Blade Care

Store Japanese saws in blade guards. The thin teeth damage easily. Most modern versions have replaceable blades, making resharpening unnecessary.

Wipe the blade with a light oil after use to prevent rust. A quick pass with camellia oil or paste wax protects the steel between sessions.