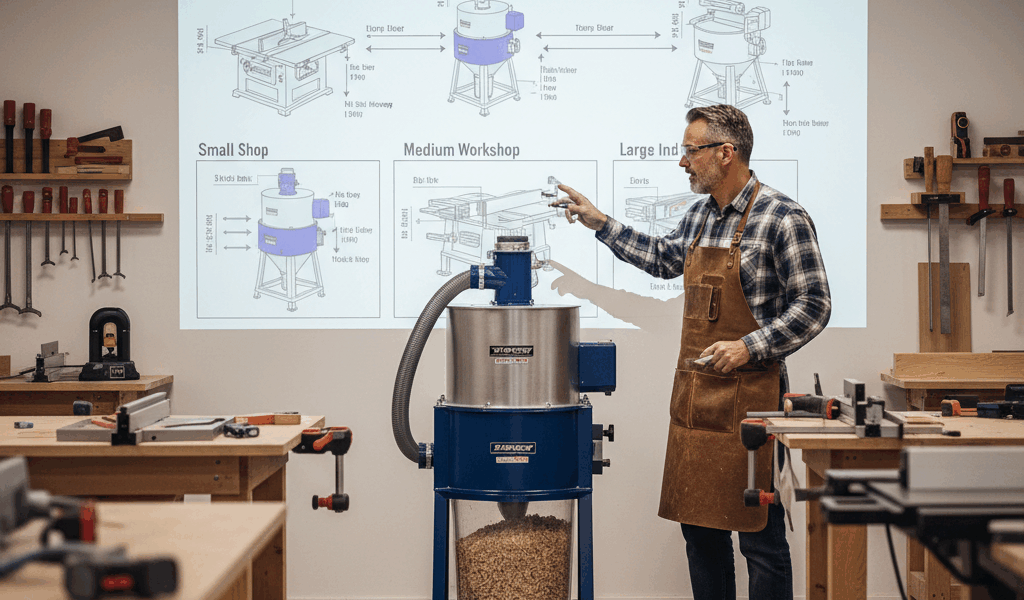

Dust collection has gotten complicated with all the CFM ratings and ductwork calculators flying around. As a woodworker who has set up several shop dust collection systems over the years, I’ve learned that getting the sizing right matters more than the brand name on the collector. Today, I’ll share everything I know about choosing the right dust collector size for your shop.

Assessing Your Dust Collection Needs

Start by listing every dust-producing tool in your shop. Each tool has different dust generation characteristics — a small random orbital sander produces a fraction of what a 15-inch planer throws off. Work through the list and look up the CFM (cubic feet per minute) rating for each tool, either in the manual or on the manufacturer’s website.

Calculating Total Airflow

- Add up the CFM ratings of all tools you realistically expect to run at the same time. If you work alone and only use one machine at a time, design for the highest single-tool CFM need. If you run multiple machines simultaneously, add those CFM values.

- Build in a buffer for longer duct runs or unexpected needs. Systems always underperform calculations slightly in real conditions.

Considering Static Pressure Loss

Static pressure loss is the performance hit your dust collector takes from friction and obstacles in the ductwork. Long duct runs, 90-degree elbows, and narrow ducts all increase static pressure and reduce effective airflow at the tool. I’m apparently an “oversized duct, gentle bends, shortest run possible” person and that approach always works better for me while relying on a small collector to push through a complicated duct layout never does.

Online calculators and charts can estimate static pressure loss for your specific layout. Use those numbers to confirm your collector has enough capacity after accounting for the ductwork resistance.

Selecting a Dust Collector Type

Portable dust collectors are affordable and movable — the right choice for a small shop or single-station use. Central dust collectors connect to multiple points throughout a larger shop with higher CFM capacity for simultaneous tool use. Cyclone dust collectors add a separation stage before the filter that removes larger chips and debris, reducing filter clogging and extending filter life significantly. For heavy production work with a lot of chip volume, a cyclone is worth the additional cost.

Determining Horsepower and Motor Specs

Higher HP motors move more air and overcome greater static pressure, but a motor that’s oversized for the ductwork wastes energy and money. Match motor power to your calculated CFM and static pressure needs. Check starting torque specs to confirm the motor can handle the load during startup — this matters more in cold shops.

Filtering and Micron Levels

The filter micron rating determines what size particles get captured versus returned to the air. Most woodworking applications are well-served by a 1-micron filter. For finer materials or any setting where air quality standards are more demanding, HEPA filtration is the right choice — it captures particles down to 0.3 microns.

Balancing Costs and Capacity

Oversizing a dust collector wastes money upfront and in ongoing electricity costs. Undersizing creates health risks and poor performance. Research models in your capacity range, compare efficiency ratings and filter maintenance requirements, and factor in long-term operating costs alongside the purchase price.

Trusted Brands

Oneida Air Systems, Jet, and Grizzly are consistently well-regarded in the woodworking community for durability and parts availability. Warranty terms and customer service reputation matter on a shop machine that you’ll depend on for years.

Sizing Checklist

- List all tools with their CFM requirements.

- Calculate combined CFM for simultaneous use.

- Estimate static pressure loss from your ductwork layout.

- Select collector type (portable, central, cyclone) based on shop size and usage patterns.

- Match motor horsepower to your airflow and pressure calculations.

- Choose filters based on micron rating and the dust your tools produce.

- Balance purchase cost against capacity, power draw, and maintenance.

- Choose a brand with strong reviews and parts availability.

One Final Thought

Getting dust collection right is one of the most important shop investments you can make — both for the quality of your work and your long-term health. Do the CFM math, account for your ductwork losses, and size the system to match your actual simultaneous usage rather than your theoretical maximum. That’s what makes proper dust collection endearing to serious woodworkers: it’s an infrastructure investment that pays back every single day you’re in the shop.

Recommended Woodworking Tools

HURRICANE 4-Piece Wood Chisel Set – $13.99

CR-V steel beveled edge blades for precision carving.

GREBSTK 4-Piece Wood Chisel Set – $13.98

Sharp bevel edge bench chisels for woodworking.

As an Amazon Associate, we earn from qualifying purchases.