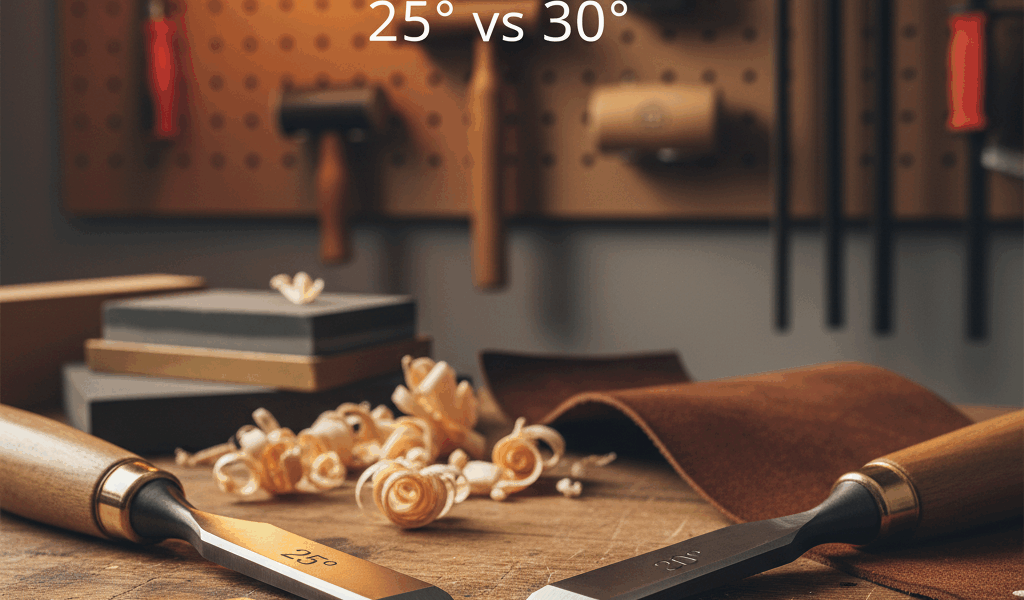

The chisel bevel angle debate has gotten complicated with all the sharpening systems and micro-bevel techniques flying around. As someone who’s maintained a set of chisels through years of actual shop use, I’ve learned that the angle question has a cleaner answer than the forums make it seem. Today, I’ll share everything I know.

When sharpening chisels, the bevel angle directly affects cutting performance and edge durability. The two most common angles — 25 degrees and 30 degrees — serve different purposes in the workshop. Understanding when to use each angle helps you match the tool to the task.

The 25-Degree Bevel

A 25-degree bevel creates a thinner, sharper edge that requires less force to cut. This angle works well for paring operations and softwoods where the edge won’t face heavy impact. The shallower angle slices through wood fibers with minimal resistance, making it ideal for fine trimming and fitting joints.

The downside is edge retention. The thinner edge dulls faster and chips more easily when chopping or working hardwoods. You’ll spend more time at the sharpening station, which may or may not matter depending on your workflow.

The 30-Degree Bevel

A 30-degree bevel produces a more robust edge that holds up to heavy chopping and dense hardwoods. The extra metal behind the cutting edge supports the tool during mallet work and resists chipping when striking knots or difficult grain.

The trade-off is cutting effort. The steeper angle requires more force to push through wood, which becomes noticeable during extended paring sessions. For general-purpose work and mixed wood species, this angle provides a good balance between sharpness and durability.

I’m apparently a 30-degree person for bench chisels — it works for me in the variety of work I do while 25-degree edges always seem to chip at the worst possible moment. For dedicated paring chisels, I’ll go down to 25. Each chisel in the rack earns its angle.

Splitting the Difference

Some woodworkers use a micro-bevel approach: grind the main bevel at 25 degrees, then add a small secondary bevel at 30 degrees during honing. This gives you most of the cutting ease of a 25-degree edge with the durability of a 30-degree edge. The micro-bevel is quick to touch up between major sharpening sessions.

Wood Type Considerations

For softwoods like pine and cedar, a 25-degree angle cuts cleanly without excessive force. The lower density material won’t damage the thinner edge during normal use.

For hardwoods like oak and maple, a 30-degree angle stands up better to the dense grain structure. The extra support prevents edge rolling and micro-chipping that happens with thinner bevels in hard material.

Task-Based Selection

Match the angle to the work:

- Paring and trimming: 25 degrees for easy slicing

- Chopping mortises: 30 degrees for impact resistance

- General bench work: 30 degrees or 25 with 30-degree micro-bevel

- End grain work: 30 degrees to prevent edge damage

That’s what makes the bevel angle decision endearing to us woodworkers — it’s one of those small choices that compounds over a whole project. The right angle means you’re reaching for the sharpening stones half as often, and the tool feels like it’s working with you instead of against you.

Sharpening Time Investment

A 25-degree bevel removes less metal and sharpens faster on waterstones or diamond plates. A 30-degree bevel requires more material removal but holds the edge longer between sharpenings. Calculate which approach saves time based on your typical workload.

For dedicated paring chisels used exclusively on face grain, the 25-degree angle makes sense. For chisels that see varied use including chopping and hardwood work, the 30-degree angle reduces maintenance frequency and prevents edge failures mid-project.

Recommended Woodworking Tools

HURRICANE 4-Piece Wood Chisel Set – $13.99

CR-V steel beveled edge blades for precision carving.

GREBSTK 4-Piece Wood Chisel Set – $13.98

Sharp bevel edge bench chisels for woodworking.

As an Amazon Associate, we earn from qualifying purchases.