Chop saws versus miter saws have gotten complicated with all the “they’re basically the same thing” advice and conflicting recommendations flying around. As someone who has used both in different contexts, I’ve learned what actually distinguishes these tools and when that distinction matters. Today, I’ll share everything I know.

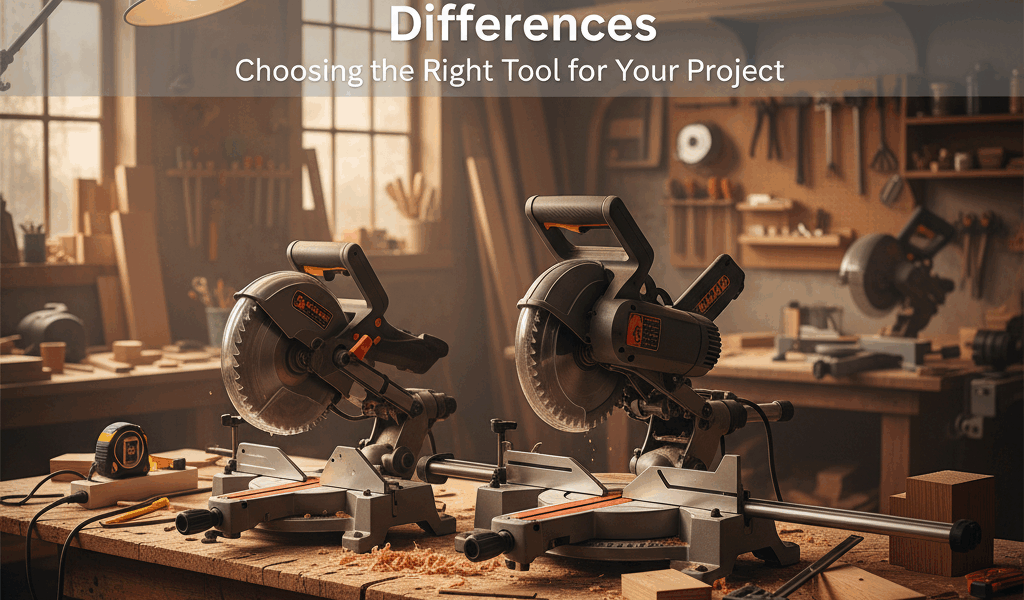

Chop Saw vs. Miter Saw: What’s Actually Different

The Chop Saw

A chop saw is a heavy-duty power tool built for cutting through dense, hard materials — primarily metal and masonry. The blade is an abrasive disc rather than a toothed saw blade, which is what enables it to cut through steel, concrete, and similar materials. The design is straightforward: a pivoting arm with an abrasive disc that drops straight down through the material. The fence is fixed at 90 degrees to the cut. No miter angle adjustment, no bevel capability — just a powerful straight cut for high-volume work on hard materials.

The trade-off for that power and material capability is the lack of precision adjustability. Chop saws don’t do angled cuts. They’re industrial tools for cutting rod, pipe, rebar, and similar materials to length, not for woodworking joinery.

The Miter Saw

A miter saw is built for precision cutting in wood, plastic, and light aluminum. The pivoting blade rotates left and right on a calibrated table to produce miter angles. Compound miter saws also tilt the blade for bevel cuts. Sliding compound miter saws extend the cut length with a sliding arm. This flexibility — crosscuts, miters, bevels, and compound cuts — is what makes the miter saw the primary cut-off tool in a woodworking shop or on a finish carpentry job site.

That’s what makes miter saws endearing to us woodworkers — the combination of precision and versatility. Setting an angle, locking it, and cutting the same miter repeatedly across multiple pieces produces consistent results that hand tools and chop saws simply can’t match.

Which One You Need

The choice is straightforward when you know the application. Working with metal, concrete, or masonry: a chop saw. Woodworking, trim work, framing, or any application requiring angled cuts: a miter saw. The two tools don’t overlap in practice — they serve different materials and different precision requirements. Many woodworking shops have a miter saw as a primary tool; industrial metal shops have chop saws. A general contractor might have both for different phases of work.

The confusion between them usually comes from how they look — both have a pivoting arm that drops onto the material. The material they’re designed to cut and the cut precision they offer are fundamentally different.

One Final Thought

If you’re doing woodworking or finish carpentry, you want a miter saw. If you’re cutting metal or masonry regularly, you want a chop saw. Don’t buy one hoping it serves the other’s purpose — the design differences are real and they determine what each tool can do well.